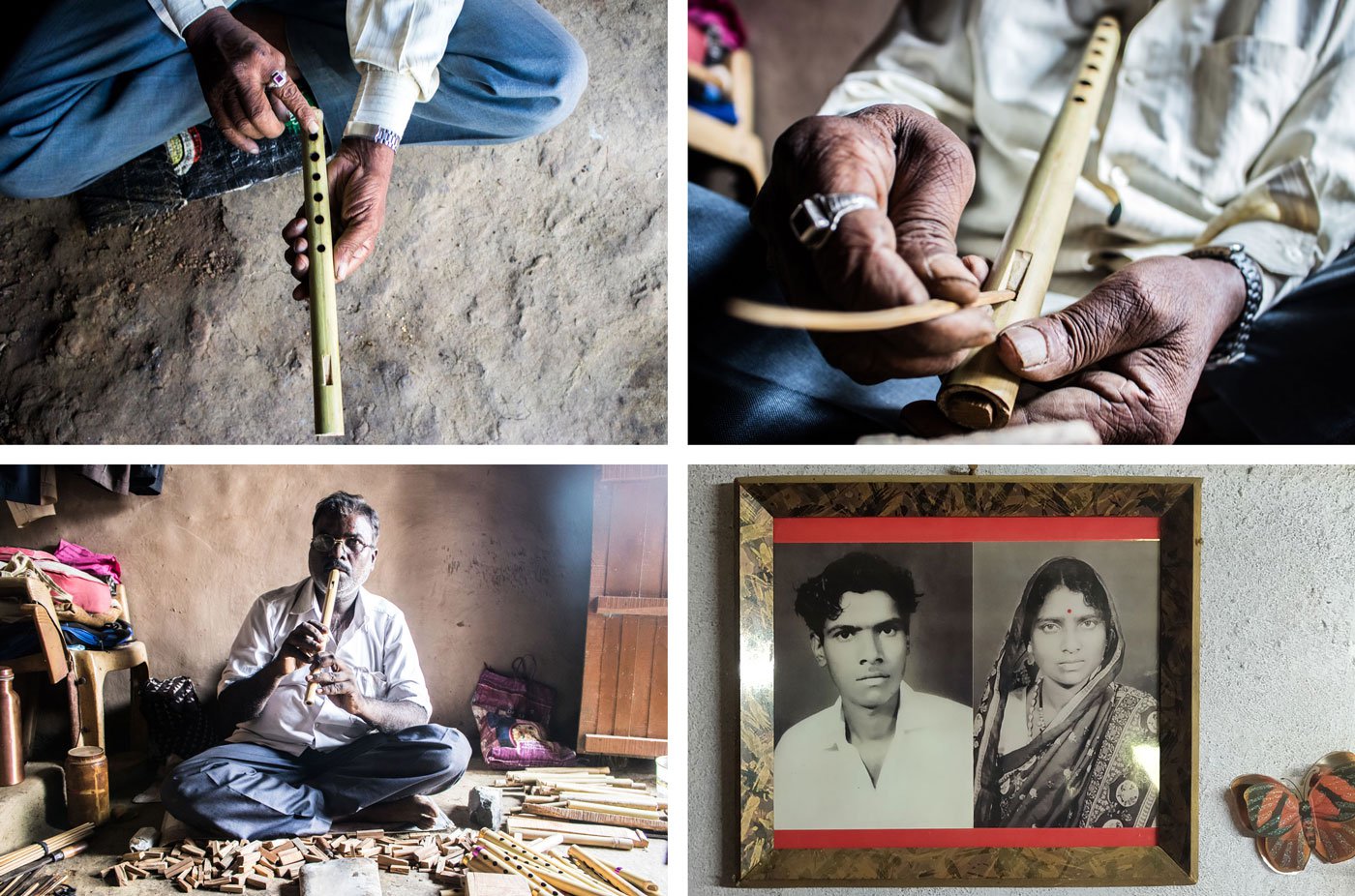

It’s been a silent year for Dinkar Aiwale, long months during which his flutes have made barely any music. “This instrument directly comes in contact with the mouth. There’s risk involved in such contact in these corona times,” he says, sitting in his workshop within his mud-and-brick house.

Next to him is an old wooden box full of tools. If he were to use these as he did until a year ago, it would take him less than an hour to convert the raw laguna yellow bamboo sticks, stacked neatly in one corner, into a fine flute.

Instead, 74-year-old Dinkar simply stares at the lifeless bamboo as we speak. His work has come to a near-standstill since the lockdown began in March 2020 – after he had worked for about 150,000 hours perfecting his craft, putting in 10 hours a day for 250 to 270 days a year, for over five decades.

From the time he started making flutes, at the age of 19, Aiwale has never taken such a long break. And in the year gone by neither has he traversed the hundreds of kilometres he usually did, selling flutes in many jatras (fairs) across Maharashtra and Karnataka. Large gatherings like the jatras are yet not permitted.

Top left: The flute-makers toolkit with (left-to-right) a hacksaw blade, two types of patli , hatodi , three types of chaku (knives) a cleaning chaku , two varieties of masudichi aari , pakad , two aari for making holes, and the metal rod on top is the gaz. Top right: The tone holes on a flute are made using these sticks which have marks for measurements. Bottom: Dinkar Aiwale has spent over 1.5 lakh hours perfecting his craft and now takes less than an hour to make a flute

Even before the lockdown, Dinkar Aiwale’s family – they belong to the Holar community, listed as a Scheduled Caste – was the only one engaged in handcrafting flutes in Kodoli, his village of around 29,000 persons (Census 2011) in Panhala taluka of Maharashtra’s Kolhapur district.

In the past, men from his community, who were traditionally shehnai and dafda (tambourine) players, would often perform at religious or social gatherings, going from village to village. They even formed a band, and Dinkar was among the 14-15 musicians to join the group in 1962. He was 16 then, and started to accompany his father, the late Baburao, after dropping out of school in Class 8. Over time, he played in two bands, one from his own village, another from a neighbouring village, both called ‘Hanuman’ band.

“Like my father, I played clarinet and trumpet in the band for 38 years,” Aiwale says, with evident pride. He speaks evocatively of this inheritance: “ Vajantri cha mulga jar radla tar to svaratach radna [When the child of a band musician weeps, even his crying is in tune].” He also played the flute and shehnai with equal ease and skill.

However, the income from playing with the band was too little and never consistent. “A group of 14-15 people would collectively get 60 rupees back then for a three-day function,” he recalls. That left him with barely Rs. 4 for three days of band-work. So Dinkar had to pick up more work as a wage labourer. But when that too did not suffice, he wanted to acquire some other skills.“There was no other option,” he says talking about how he began making flutes, “How could I sustain my family? Wage labour was not enough.” Ten hours of work as an agricultural labourer in 1960s fetched him a mere 10 annas (1 anna is 1/16th of a rupee). Dinkar worked as a labourer for roughly two decades until he found something “that could help me eat two meals a day,” he says.

His answer lay 20 kilometres away in Savarde village, with his father-in-law, the late Dajiram Desai, who was to teach him how to make bamboo flutes. He continued to occasionally travel and perform with the band too. (In the year 2000, his travels came to a halt when his wife Tarabai underwent a coronary bypass surgery and he was needed at home to take care of her. Tarabai passed away in 2019).

Their son, 52-year-old Surendra, has also inherited the knowledge of making the fine instrument from his father. (Dinkar and Tarabai’s two daughters are married and one passed away). Surendra began selling flutes by the age of 13, and when he was 16, like his father had done, he too dropped out of Class 10 to work full-time. “Initially, I hesitated and felt ashamed [of selling flutes on the street],” he says. But, adds Dinkar, “But when you have to feed your family, you can't afford to be hesitant.”

Until the lockdown began last years, Surendra regularly travelled with his father to many places including cities such as Pune and Mumbai to sell them. But he and Dinkar were unable to sell a single flute between March and October 2020. The only order they received came in November, for five dozen flutes of different sizes (the longest he makes is roughly 2.5 feet), for a dealer in Sangli town, some 55 kilometres from their village. They sold the lot – 60 flutes – for Rs. 1,500. During those months of no sales and no earnings, the family depended on the money sent by children and grandchildren working in the cities.

Dinkar Aiwale handpicks the finest quality bamboo from markets in Ajra and Chandgad taluka of Kolhapur district for crafting his flutes. Right: After cutting the raw bamboo stick as per the required length, he swiftly moves in a metal rod to hollow out the bamboo

Even after November, business has not picked up. The last jatra that Dinkar and Surendra went to was over a year ago, on February 21, 2020 in Audumber village in Sangli district . “In any jatra , we could easily sell around 2-2.5 gross (1 gross = 144 units) flutes,” Surendra says. The Aiwales used to prepare in advance for a fair by handcrafting over 500 flutes.

Every year, they covered more than 70 jatras , across villages in western Maharashtra and northern Karnataka. “We hang at least 50 flutes on a stand and keep playing our bansuri . Only if the music delights people, they are going to buy the flute,” says Dinkar.

He handpicks the finest quality bamboo from markets in Ajra and Chandgad taluka of Kolhapur district for crafting these flutes. A shenda, roughly 8 to 9 feet, costs Rs. 25 now. “It used to pay 50 paise for it in 1965 when I started making flutes. With one shenda , we can easily make 7-8 flutes,” Dinkar explains.

For the fipple flutes (held perpendicular to the ground), after cutting the raw bamboo stick as per the required length – he makes more than 15 different sizes – he swiftly uses a metallic rod to make the bamboo hollow. Even a slight error can result in a poor quality flute that produces mediocre tones.

Left : Before the wooden cork can be placed in the blow hole, it has to be shaped to match the flute’s dimensions. Right: Hammering the cork into the blow hole

Before making the flutes, Dinkar cuts off a log of sagwan (teak wood) weighing a kilogram into smaller rectangular pieces known as khuttya in Marathi (cork or fipple plug). After cleaning the bamboo, the teak cork is placed in the blow hole using a hammer to prevent the blown air from escaping.

Dinkar’s wife Tarabai used to make flutes too. She was particularly deft at making khuttya “As a memory, I’ve safely kept this khuttya made by her,” he says, in tears.

The tone holes on a flute are made using teak sticks which have marks for measurements. Dinkar has 15 such sticks to do this task accurately. He and Surendra would go to workshops in Kolhapur city, around 30 kilometres away, where skilled harmonium makers mark these measurements.

Then the marked holes are manually drilled using traditional instruments. “A drill machine cracks the entire flute, so we don’t use any machines,” says Dinkar, meticulously carving out a masud (nest) near the blow hole or the north end of the flute. “The masud acts like the nose of the flute. It helps circulate the air.”

Left: Dinkar holding the reference stick and a piece of bamboo together before marking the tone holes. Right: The temporary holes marked on the flute are made permanent with a heated iron rod

He then heats at least six iron rods ( gaz in Marathi) to make proper holes in the bamboo. “Usually, we take at least 50 flutes at a time and finish off this process in three hours,” Dinkar says. Early in the morning, he heats the rod and water (for bathing) in the same chuli (mud stove). “This way we can finish both the tasks,” he adds.

After drilling the tone holes, he polishes the flute using sandpaper. Now the extra part of the cork is sliced off to give it a curve. This helps create a small passage for the blown air between the north end of the flute and the nest.

“Every piece of bamboo goes through our hands at least 50 times,” says Dinkar, explaining the painstaking process. “A flute looks simple, but it’s not easy to make one.”

Surendra’s wife, Sarita, who is in her 40s, also works on drilling the marked holes, heating the rod, cutting the log of s agwan and making khuttyas . “For us, this skill is god gifted,” she says, “We don’t have to learn it.”

Left:

Right: Marking out a

masud

(nest) near the blow hole. Right:

Drilling permanent holes in the flute using a metallic rod

Before the lockdown, at the jatras , Dinkar and Surendra usually sold bigger flutes (used by musicians) for Rs. 70 to 80 each, and the smaller ones for kids for Rs. 20-25. A dozen flutes of mixed size got them Rs. 300 to 350 until a year ago.

The Aiwales also make transverse flutes or the side-blown flute that is played parallel to the floor. “We call it the Krishna flute. People hang it outside their house as it is considered a good omen,” Dinkar says. “Each Krishna bansuri sells for at least Rs. 100, and there’s a lot of demand for it in the cities,” he adds. And while the prices they get hardly cover their intense labour, “it still brings in enough money,” says Dinkar referring to pre-lockdown times.

After five decades of crafting fine flutes, the attention to detail and minute work has affected Dinkar’s eyes. A few years ago, he had developed cataract. “Now I can see clearly,” he says referring to two surgeries in 2011 and 2014, “but this work also causes a lot of backache.”

If someone were to ask him ‘what did you make of your entire life?’, Dinkar says, “I can proudly tell them that only because of this flute making, all my children and grandchildren could study and progress in life; I could put them on right track. This skill gave us everything.”

Top left: The permanent holes Dinkar has made in the flute. Any error here leads to poorer notes and tunes, affecting the quality of the flute. Top right: D inkar meticulously carves out the masud (nest) that acts like the nose of the flute. Bottom left: Surendra Aiwale, 52, who is also a flute-maker and a flautist, is the last generation of the Aiwales to keep the art form alive. Bottom right: An old photograph of Dinkar and Tarabai

Since 2000, Dinkar has also been teaching others to play the flute, and has come to be known as ‘Master’ in Kodoli village. His students – he estimates there have been at least 50 so far – have included doctors, teachers, farmers and businesspersons from nearby towns and villages. He does not charge any fee for these lessons. “If people remember my name, that’s enough,” he says.

Though the lockdown and its aftermath have hit his business hard, Dinkar is confident that the demand for the flute will remain robust. But he also knows that the young generation’s aspirations are different, and few want to learn the art of making flutes. “You can earn enough money [in this], but who wants to work so hard now? One finds time when one is passionate. It is all about your will,” he says.

At 74, that will remains resolute in Dinkar, and he continues crafting flutes, though he gets breathless sometimes while playing a flute now. “It [making and playing flutes] will live as long as I do,” he says.