Almost every year, for as long as anyone can remember, the Purbannapara community of Makardah village in Howrah, West Bengal, has held a Tubri protijogita or competition for making the brightest, biggest, and longest-lasting tubri . A kind of firework, the tubri looks rather like a Christmas tree and can loosely be called a Roman candle, but there is no real equivalent in the western world. In Bengal, those village men who are experts in the craft teach their nephews and other boys to make a tubri , along with other types of fireworks, around the time of Kali Pujo, the local version of Diwali. The competition is typically held a week or two after Diwali, as an extension of the Festival of Lights.

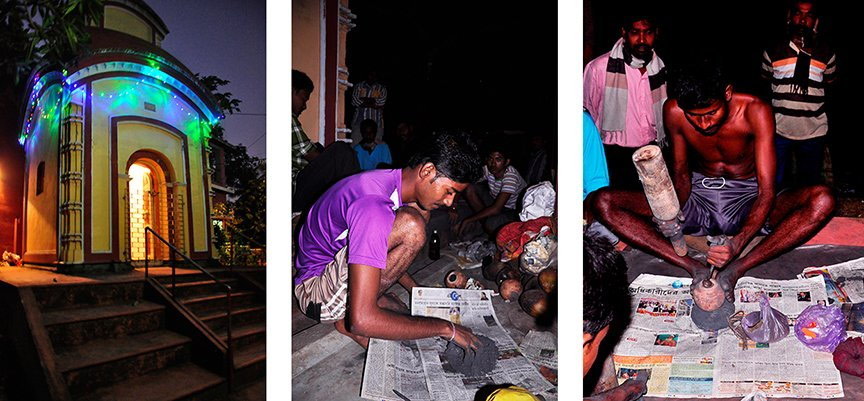

In the early evening, Purbannapara's central courtyard, where all festivals are held, is prepared by erecting two bamboo poles, tied to one another. The resulting single pole will serve to measure the height of the competing tubris , which can reach as high as 70 feet.

As darkness gathers, so does the audience, until every window nook and the top of every wall will be spoken for

Festivities commence with a fancy-dress competition,"Go As You Like," featuring the young, and the young at heart.

Meanwhile tubri making teams, including two from other villages in southern Bengal, have arrived and are assembling their competition entries, each in a different hidden corner of the village. A tubri consists of a powdered mixture of salpeter, sulphur and charcoal, combined with iron filings, stuffed tight into a spherical shell made of baked earth. A small hole in the top of the casing allows the powder to be lighted. Each team has its own secret formula for the quantities and graininess of the ingredients, which have to be pounded and mixed fresh for maximum effect.

As more exotic metal shavings become available in local factories, the firework makers have been experimenting with these as well. One team is reported to incorporate antimony, for instance. Aluminium shavings are also common, as a substitute for iron flakes. (Whereas iron burns in yellowish sparkles, aluminium burns a brilliant white, which may be prettier; but aluminium also reduces the height and lifespan of the resulting tubri .)

All the teams, however, appear to buy the earthenware casings, which have to withstand tremendous heat and pressure, from a single aged potter. He may be the one irreplaceable key to the tradition.

One team has chosen to prepare its entries behind the village's Shiv temple, whose front has been dressed for the occasion. The powders are ground, mixed, and then pounded tight into the casing, the diameter of which is limited by the competition rules to four inches.

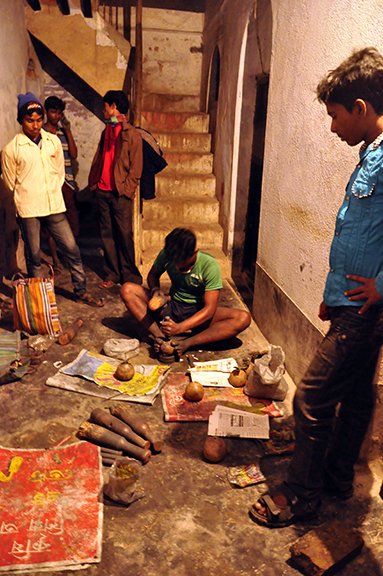

A rival team has found shelter in the landing of one of Purbannapara's homes

One of its two finished entries for the competition will end up a winner

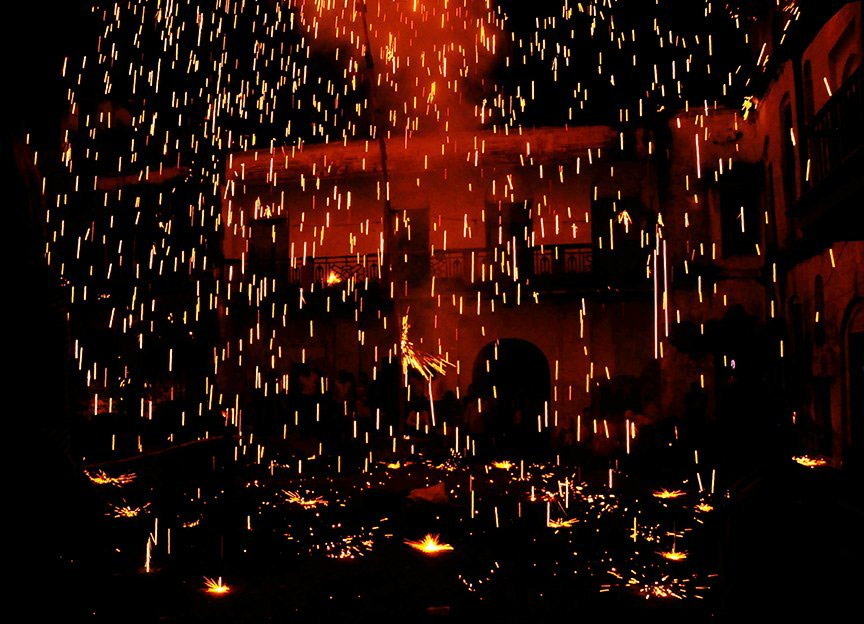

On this night of November 2013, 124 tubris will flare. The other visiting team, behind the temple, will also take home one of the top cash prizes of a few thousand rupees, donated by a local entrepreneur.

The competition commences with the lighting of a tubri. The firework is set inside a cubical metal frame, designed and made by a local engineer, in order to protect the audience from flying fragments of what is essentially a bomb should the casing burst, which happens often (right).

A tubri soars into the sky above the courtyard

On a rooftop, lit up by a tubri, judges grade the height and other attributes of the fireworks. They wear hats to protect their heads from falling embers

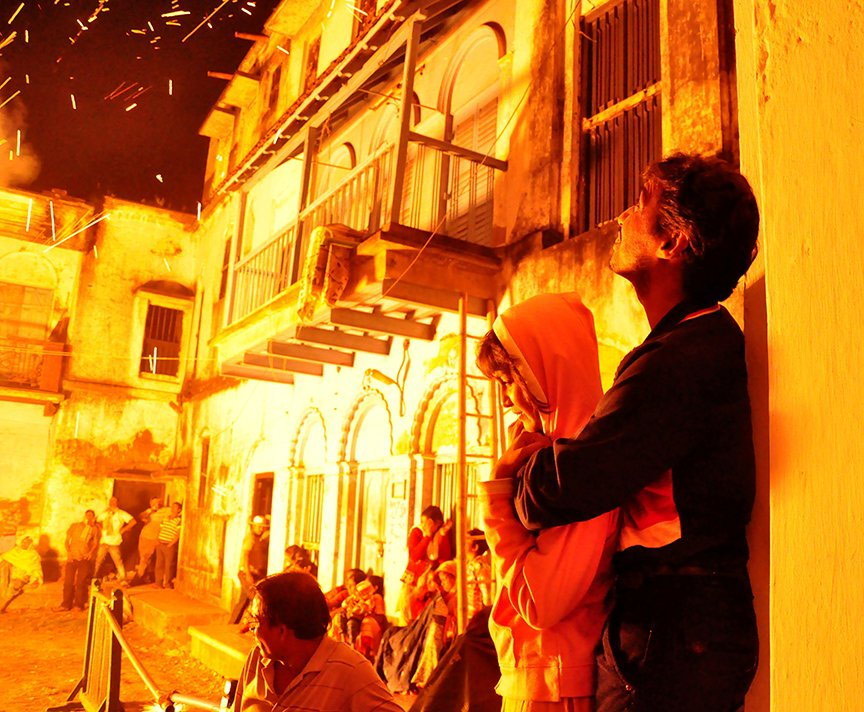

Down below, a father and daughter enjoy the fear and thrill of a tubri roaring above...

...and wince when one blows up with a deafening bang. The enthralled audience is oblivious to the embers falling at its feet from a dying tubri.

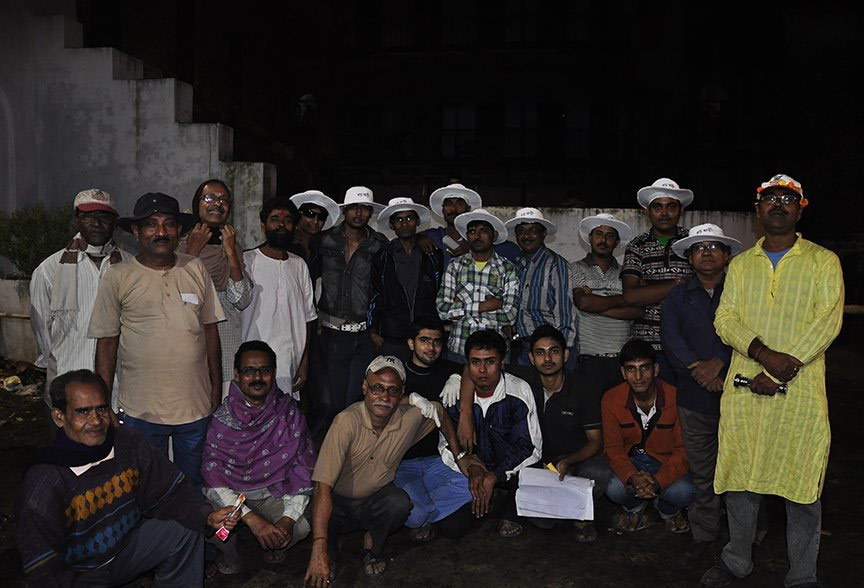

After the exhilarating competition and prize giving are over, well past midnight, the organisers pose for a group photo. The outside teams departed long before, without collecting their prizes, because if the police stopped their rented car late at night and smelled explosives, they would get into trouble.

Till next year!