“I’ve been amazed only once in my life,” says 60-year-old Bhaiyyan Kushwaha, while describing Mangal Singh’s water turbine. It’s a hot afternoon in Dashrara, a village in Lalitpur district of Uttar Pradesh. Bhaiyyan is scattering wheat seeds in one part of his 15-acre farm. “This was barren land until the turbine made irrigation easy [for a while], some 30 years ago.”

He hesitates before describing how the turbine worked. “I am not educated,” he mumbles. He first saw a wooden wheel near the Sajnam river, close to his land, in 1987, at a small check dam built by local labourers. “The wheel was connected to a ‘gearbox’, and when water would flow in the wheel would turn and the water would reach us [some 1-2 kilometres away]. All I had to do to was insert wooden ‘gates’ to start or stop the flow of water through the machine.

But it wasn't the machinery that surprised Bhaiyyan as much as the conversation that followed: “When I asked how much it would cost, he said it was free. The turbine needed neither diesel not electricity to supply water. I was shocked.”

* * * * *

Mangal Singh, 71, belongs to an affluent Rajput landowning family in Bhelonilodh village of Bar block in Lalitpur district. Growing up in a farming community, he knew how much the dependence on water contributed to poverty in his and other villages of the Bundelkhand region. While the Sajnam river brought water, pumping from it required power or diesel – and a significant monetary investment.

Left: This was barren land until the turbine made irrigation easy [for a while] some 30 years ago', says Bhaiyyan Kushwaha. Right: Khushilal Kushwaha remembers that his father used the Mangal Turbine to water their fields in the early 1990s

“A large part of the farmer’s savings were slashed by the diesel bills. My desire to help farmers led me to think about the possibilities of lifting water from streams and canals without depending on diesel or electricity,” Singh says. “I used to play with pinwheels [a simple wind-driven spinning toy] as a child. In my 30s, I had a brainwave – what if a large pinwheel, or simply, a wheel, could help pump water?”

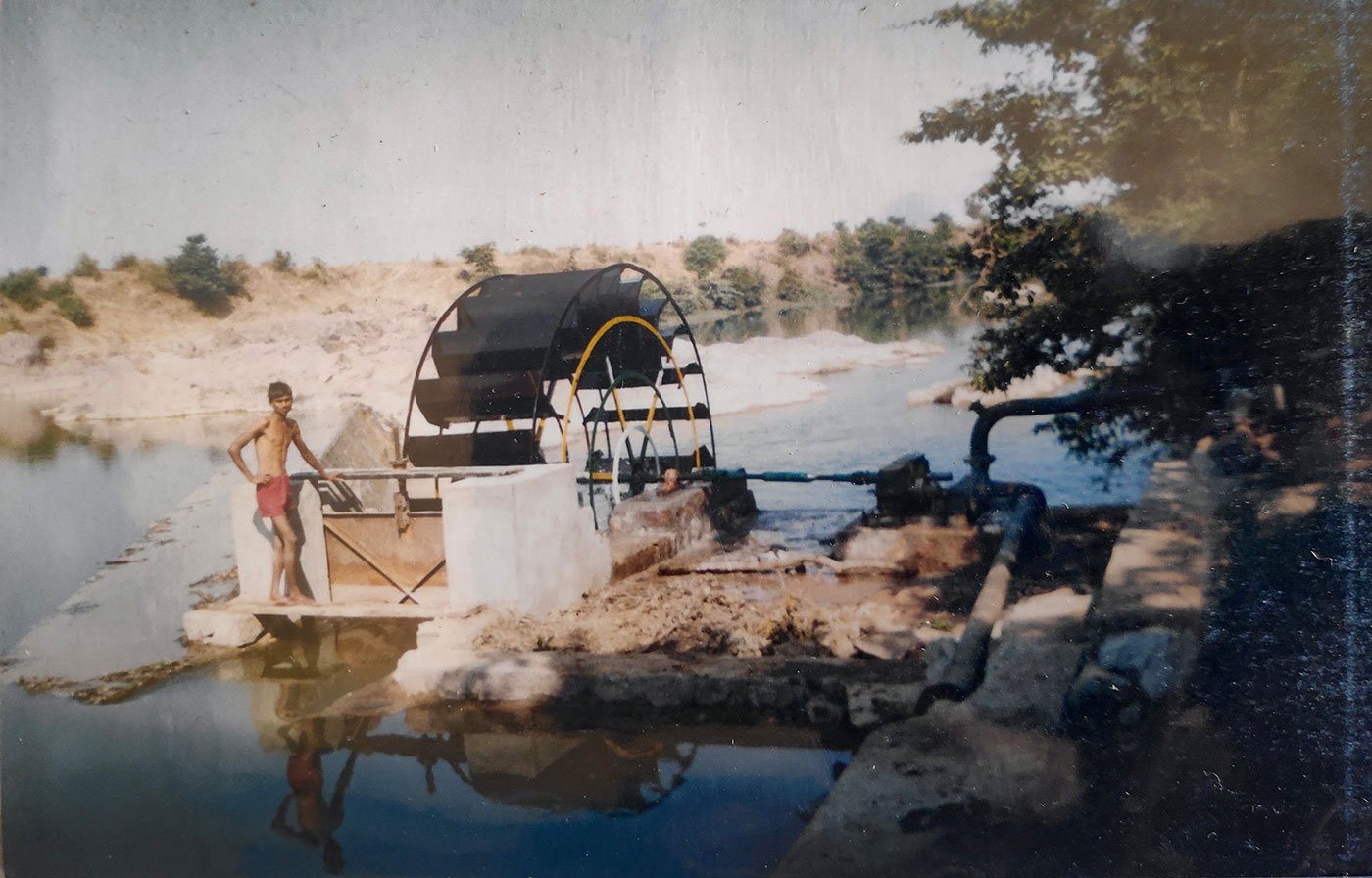

Around 1986, Singh built a wooden wheel (two-metres in diameter, made from local babool wood) fabricated with 12 blades (flat wooden slabs fixed to the rim). In later years, he replaced the wood with iron sheets because wood was expensive and prone to decay in water. “The wheel was then mounted on a steel shaft and supported by two bearing blocks. The shaft was coupled with a gearbox for stepping up the speed of rotation. The gearbox had two ends – one end had a centrifugal pump to lift water and supply it till up to two kilometres through pipes, and the other end was mounted with a pulley.” By the 1990s, Singh improvised further and began to connect the pulley to run farm machines like a crusher or grinder.

In a 1998 study on the water resources of Bundelkhand, researchers from the Indian Institute of Technology, Delhi, found much to appreciate in their analysis of the device. They said that manufacturing one turbine would cost Rs 1.8 lakhs and that “two turbines on one site have the potential to irrigate 200 hectares of land” and “considering 500 suitable hydrosites... for installing the Mangal Turbine, it is estimated that...25 MW energy can be easily generated.”

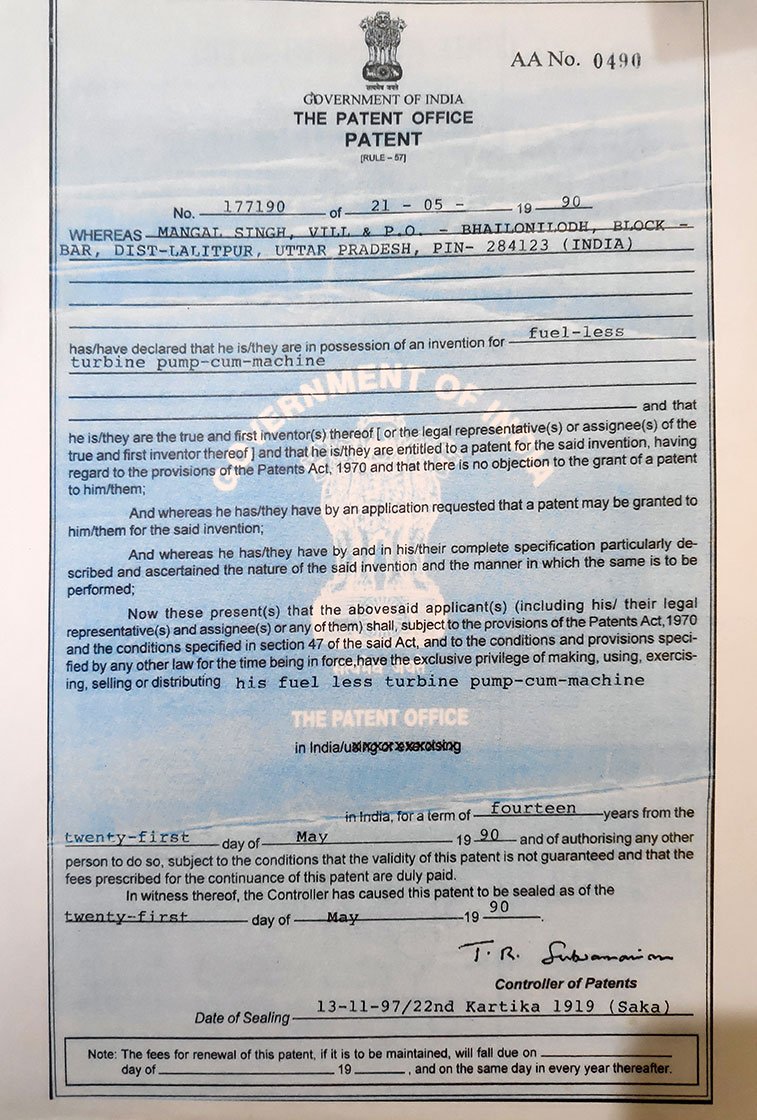

Singh, aware of the device’s utility, had already patented it in 1997 (patent no. 177190 of November 13, 1997) at the Patent Office, Delhi, which is administered by the Controller General of Patents, Designs & Trade Marks. But that did not help take his innovation far.

* * * * *

Khushilal Kushwaha, 41, remembers that his father used the Mangal Turbine (as the local Hindi press started calling it) to water their fields in the early 1990s. “I was 12-13 years old then. I remember that from almost no crops, the availability of water meant we were growing many times more wheat and peas.” Kushwaha wonders how Singh managed to build the turbine without any technical expertise. (Mangal Singh could not complete his Bachelor’s in Science at the Government Degree College in Tikamgarh, Madhya Pradesh, because of a students’ protest in 1967.)

Left: An album photo of the turbine when it was operational at the local ghat in the early 1990s. Right: Mangal Singh at the now-silent turbine at the same ghat

“It was trial and error,” Singh says. “I constantly innovated and perfected the device at a recurring personal cost.” (He doesn't remember the amount and hasn't kept records.) And this started him off on a decades-long struggle to find funding for his idea of using the locally-made turbine for irrigation.

After the first device became operational around 1986, Singh began to spread the word. “I took my invention to people through letters. CAPART [the Council for Advancement of People's Action and Rural Technology of the Ministry of Rural Development] was among the first to get interested. In 1988, CAPART provided me with a Rs. 48,500 grant to build and install an additional prototype of the turbine in my village, Bhelonilodh.” Singh had built his first turbine in Dashrara, around three kilometres away, finding that location closer to more farms.

The Dashrara turbine had got visitors hurrying to see the installation. Among them, Singh recalls, was Sarla Gopalan, advisor to the then Planning Commission. Singh has kept her letters of support, and he shows them to me. The device was also inspected and appreciated by the Alternate Hydro Energy Center at IIT Roorkee and The Energy Research Institute, Delhi [TERI]. CAPART commissioned Singh to make a few more turbines.

Left: Singh obtained a patent for the devise in 1997. Right: But got caught in a decades-long battle with paperwork and bureaucracy

But soon, Singh says, “corruption, harassment and victimisation” started. “Government agencies would give me a low-budget project and then stop the instalments. When I would use my own funds to complete the turbine, they would send a monitoring team and impose objections such as not submitting cash books, not doing this or that. I would plead with them that I am an individual innovator, not an NGO and I cannot work like an office with various staff… but the harassment would continue.”

Much later, in 2010-11, the Ministry of Rural Development appointed B.P. Maithani, a former professor at the North Eastern Regional Centre of the National Institute of Rural Development & Panchayati Raj, Guwahati, and a former member-convenor of the north-east and central zones of CAPART. He was asked to look into Singh’s allegations.

His report discussed the projects that were sanctioned to Singh by the District Rural Development Agencies (DRDA) of Uttar Pradesh and Madhya Pradesh in their villages, along with CAPART, and records the neglect and red-tape. Maithani writes, “The tragedy was that Shri Mangal Singh could not complete most of these projects due to hurdles created in the release of funds by the sponsors.”

For example, in 1996, the report says, CAPART placed Singh under FAS ('Further Assistance Stopped') “on a trivial issue of not submitting proper utilisation report of the paltry sum of Rs 6,400 released to him for a project in 1990.”

Mangal Singh’s workshop in Bhelonilodh, where he and labourers employed by him made the turbines, now lies unused, with rusting scraps of metal and machines

“I wanted to continue the work but it was impossible to fund it,” Singh says. “I wrote infinite letters and it was only after several efforts that I managed to get myself delisted from the FAS category.” This enabled Singh to secure another project in 2001 from CAPART of building five turbines at Kanji Ghat on the Sajnam river, around 3.5 kilometres from Bhelonilodh. He had already installed one wheel there before 2001.

Work on each of the five included finding a suitable location, creating check dams, building and installing the turbine, and maintaining it. The new project, however, would remain embroiled in similar controversies.

The Maithani report notes that from the project cost of 16.8 lakhs, only Rs. 12 lakhs was released to Singh “at different times from 2003-2011”. When Singh requested that the remaining amount be released, “CAPART reminded him about seeking a formal progress report on the prescribed format and audited statement of account as a condition for any further release.”

Left: Singh at the site of the old turbine at the ghat on Sajnam river. Right: Umro Kushwaha says the turbine helped irrigate his fields; he has now leased out his land

By the early 2000s, the under-installation turbines at Kanji Ghat (as the location is locally called) came to a standstill because of what the Maithani report calls “sabotage by opponents… to the extent that several turbines and pipelines laid by Singh were damaged and destroyed.” The report notes that a person, previously “a supervisor in the Mangal Turbine workshop…with support and patronage from local administration…installed his own turbine just half a kilometre downstream of Kanji Ghat.” It submerged the assets of the Mangal Turbines being built at the same location.

* * * * *

Over around two decades, starting from 1986, Singh estimates he helped install around 50 turbines, most of them in Uttar Pradesh and Madhya Pradesh, a few in Gujarat. These were commissioned not just by CAPART but also some NGOs and the District Rural Development Agencies.

Each turbine needed maintenance and monitoring. But all of Singh’s time, he says, was taken up by the search for funding and the long battle with bureaucracy. The turbines started falling into disuse and disrepair. And the paucity of funding meant that, after some years, no new turbines could be installed.

The original Mangal Turbine at Dashrara was operational for around two decades, after which it too became dysfunctional. Its pipes and parts were stolen and taken away. "It was an extremely difficult time for me financially, which made it impossible to maintain the turbine,” Singh says. “All my energy was going in completing needless government processes, formalities and securing funds than on maintaining and improving what I had originally built."

The loss is deeply felt by the villagers. “I am now spending over Rs. 50,000 [during the October-March agriculture season] to water my fields through the diesel pump when I remember a time I used to do it for free,” Bhaiyyan Kushwaha says.

Left: Shivdayal Rajput at one of the sites where the Mangal Turbine was installed. Right: 'Today it’s far more profitable to run a groceries shop', he says

The price of pumping water using diesel (which also has an environmental cost), has added to the costs incurred by farmers. This, along with the poor returns on agriculture, have compelled many from Dashrara and Bhelonilodh to quit farming. Among them is Shivdayal Rajput, 60, whose family used the turbine to irrigate their land for some years. “Today it’s far more profitable to run a groceries shop,” he says.

Umro Kushwaha, 64, who says the turbine helped irrigate his 15 acres where he cultivated wheat, peas and cauliflower, has now leased out his land. His wife, Shyambai, says, “Only those who can afford to dig a well or buy diesel for water pumps can farm.”

Singh’s hopes now rest with the part of Maithani report that demands the government agencies help in “restoration of the turbines, withdraw charges against him, defreeze his bank account, and suitably reward him for his invention and contributions for the betterment of society”.

CAPART, however, has refused to accept the recommendations. It argues in a letter to Singh that “The report of Maithani and the recommendations/observations contained therein are not based on the examination of the terms and conditions of sanction of grant-in-aid to Shri Mangal Singh which were accepted by him…”“

But Singh has not given up. He is fighting a case against CAPART in the Supreme Court. Meanwhile, in Bundelkhand's dry fields, those wheels have ceased to turn. Their gears no longer transmit power– perhaps recognising that power can only flow from Delhi.